Phone:

+91 98490 42698

Physical address:

Side‑by‑side product families for containment and protection — Class II BSCs for biohazards and chemical fume hoods for vapors and gases.

70% recirculation / 30% exhaust via HEPA; protects product & personnel.

100% exhaust to building duct; for toxic/volatile chemicals with biohazards.

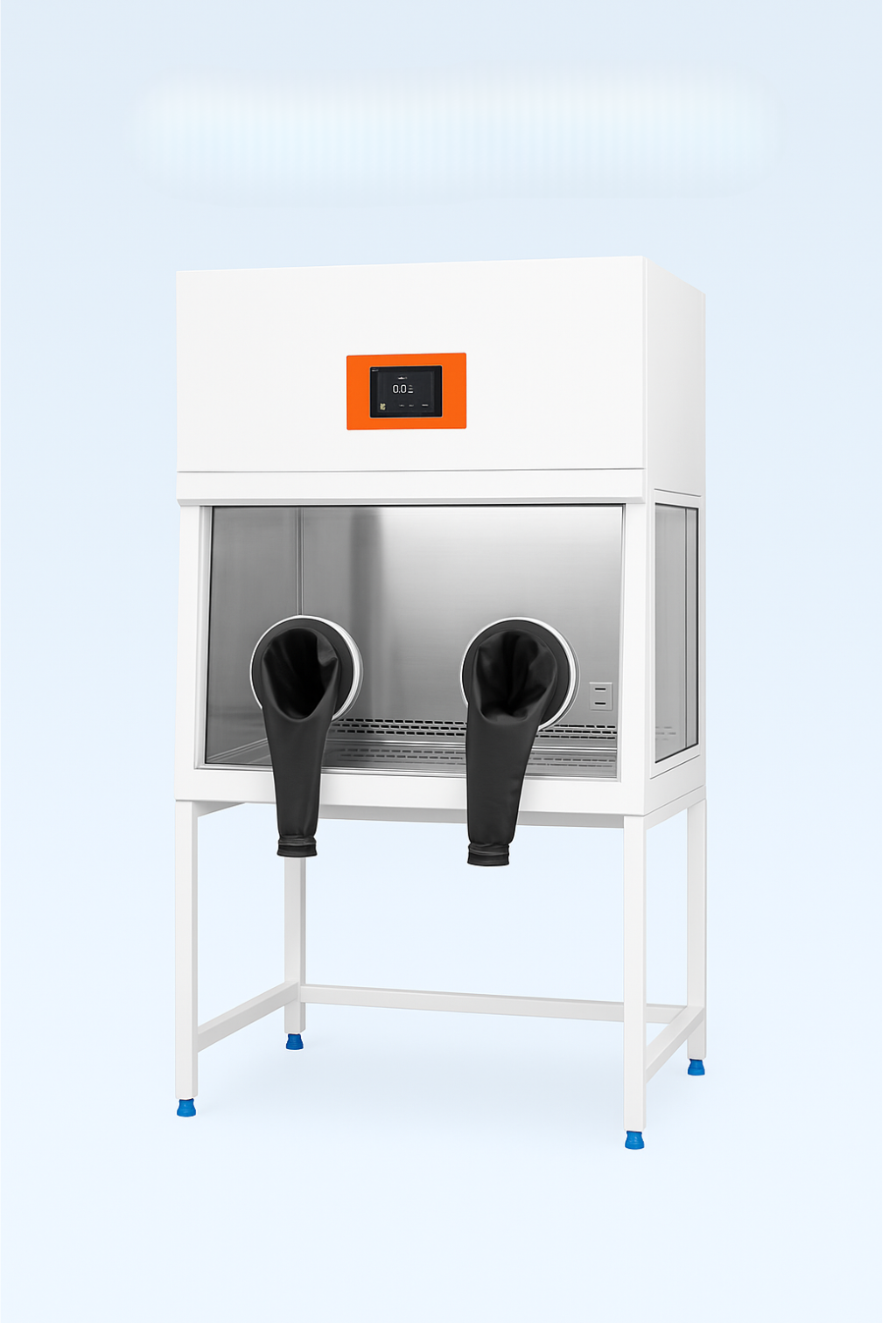

Gas‑tight enclosure with double HEPA/exhaust; highest containment.

Supply & exhaust HEPA H14 for ISO 5 work zone.

Stable laminarity with microprocessor control.

Interlocks between UV and blower/sash position.

Radius corners, spill tray, easy clean.

Utility integration with shut‑off valves.

Factory test; field certification support.

Optimized entry to maintain face velocity.

Typically ~0.5 m/s with alarms/monitors.

PP/FRP/Phenolic liners; spill containment base.

Gas, vacuum, water, and electrical service outlets.

Granite, epoxy resin, or SS depending on exposure.

Uniform illumination and stable airflow patterns.

Social Chat is free, download and try it now here!